Like everyone else, we use cookies. You can read about thier use in our Privacy Policy.

EVR Motors 31 Modi'in St. Petah Tikva 4927189, Israel.

Phone +972-3-9177055

Email info @ evr-motors.com

At EVR Motors, we developed a unique Trapezoidal Stator topology that disrupts the incremental trajectory of electric motor development.

Introducing

Our patented topology allows us to design radial flux motors that are less than half in size and weight than current advanced RFPM motors – without compromising an inch of power or a gram of performance.

Our SMC-based (Soft Magnetic Composites), three-dimensional trapezoidal tooth enables superior power and torque density, while also obtaining better flux density.

Why SMC?

Our trapezoidal coils are pre-wound and then mounted on the stator via a method that creates a high fill factor. With no end windings, the coil’s unique shape is entirely devoted to creating flux density.

Benefits

High Fill Factor

Lower BOM per kW

Power Density

Time for Motor Assembly

Tourqe Density

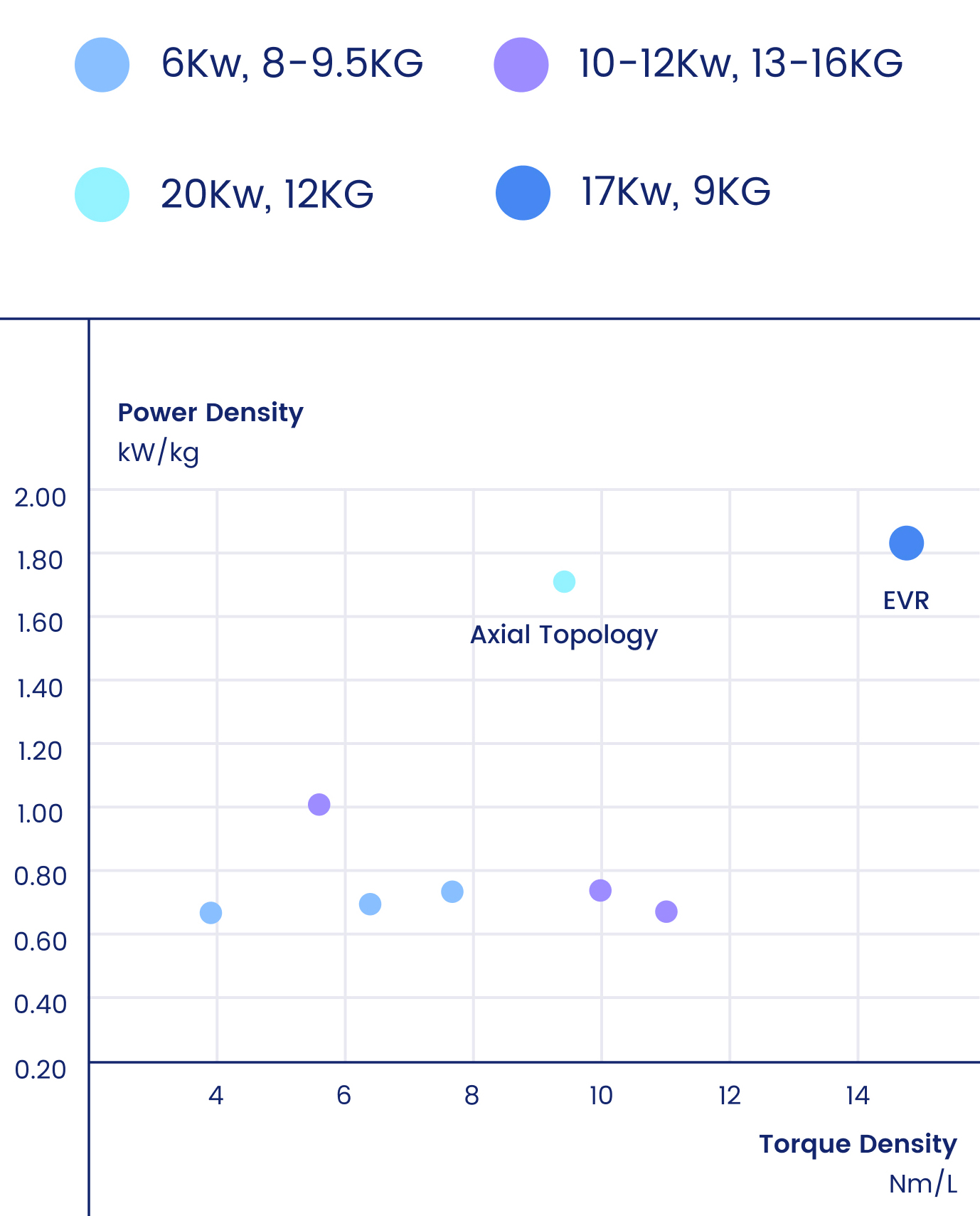

Our air-cooled 17kw Peak Power Motor, which weighs only 9 kg, offers more power per kg and torque per liter than motor performances made public by other manufacturers. EVR offers double the power and torque density.

*Comparison relevant to the US, China and Germany

Our air-cooled 17kw Peak Power Motor, which weighs only 9 kg, offers more power per kg and torque per liter than motor performances made public by other manufacturers. EVR offers double the power and torque density.

*Comparison relevant to the US, China and Germany

Rare Earth-Free Technology

Thanks to their power density, electric motor magnets rely heavily on rare earth materials. Yet rare earth materials are becoming more and more expensive, and their mining is extremely unsustainable.

Responding to the aspiration of many OEMs to reduce or eliminate the reliance on rare earth materials, EVR Motors offers a rare earth-free solution based on ferrite magnets*. Our solution retains acceptable power and torque density, at a lower cost to manufacturers and the environment.

*In some configurations

Why SMC?

Soft magnetic composites are ferromagnetic particles that come in powder form, and are used in a wide range of industries and applications. At EVR, we are using SMCs to improve performance as opposed to standard steel laminations. In addition to their high availability, high saturation & permeability levels and lower eddy current losses, SMCs exhibit the necessary flexibility to tailor material performance to specific requirements – with no added costs.