Like everyone else, we use cookies. You can read about thier use in our Privacy Policy.

EVR Motors 31 Modi'in St. Petah Tikva 4927189, Israel.

Phone +972-3-9177055

Email info @ evr-motors.com

June 11, 2025

We're expanding our partnership with Turntide Technologies to offer OEMs worldwide seamless, integrated electrification solutions. By combining EVR Motors' TS-RFPM motor technology with Turntide's Gen 6 Inverters, this collaboration accelerates innovation, reduces development risk, and speeds time to market, according to EVR CEO Opher Doron.

Read more

May 5, 2025

We inaugurated the Napino Manufacturing line for EVR Motors in Halol, Gujarat, India. It is now officially up and running!

The manufacturing line boasts high-quality manufacturing and testing capabilities, ensuring that the motors meet all standards of our customers.

Read more

December 26, 2024

The F99, India’s fastest motorcycle, set an FMSCI-certified quarter-mile record of 10.712 seconds! We’re proud to have contributed our innovative motor technology to this incredible milestone. Here’s to more successes together!

Read more

January 31, 2024

JETRO Tel Aviv for interviewed Noa Kroin, our VP of Business Development, about EVR's overseas strategies focusing on the Indian Market and the company's ongoing engagements with Japanese companies as part of the increasing demand in the Japanese market

Read more

January 7, 2024

EVR Motors, operating in India under a 100%-subsidiary – I.EVR Motors Pvt Ltd – is commissioning a greenfield plant for trapezoidal geometry coils in the country that will begin operations in Q2 CY2024.

Read more

April 1, 2023

We are honored to introduce our newest board member, Nick Rogers FIMechE FREng .With years of experience in the global automotive industry, including seven years as a board member and executive director of product engineering and research at Jaguar Land Rover, Nick brings a wealth of knowledge and expertise.

Read more

January 31, 2023

EVR is establishing a wholly-owned subsidiary, EVR India, to serve the organization’s growing customer base in the country. EVR India will manufacture electric motor coils, a patented key component of EVR’s electric motor topology, for the company’s partners in India and globally.

Read more

January 13, 2023

Signed a commercial agreement with RSB Transmissions (I) Ltd., a leading Indian tier 1, to develop, manufacture and market a line of motors for Light Commercial Vehicles.

Read more

November 23, 2022

EVR is proud and happy to partner with EKA Mobility, an electric vehicles and technology company, to provide advanced lightweight electric motors for e-buses and Light Commercial Vehicles in India.

Read more

October 6, 2022

s part of the agreement, Tsukasa will offer EVR’s electric motors to several markets in Japan, including: industrial vehicles, such as forklifts, Automated Guided Vehicles (AGV) and onboard cranes; construction vehicles; agricultural machinery and large lawn mowers; industrial robots and automated warehouses; and the Japanese small boats sector.

Read more

May 13, 2022

Under the new strategic partnership, Badve Group will manufacture in India EVR’s proprietary Trapezoidal Stator – RFPM electric motors that are significantly smaller and lighter

Read more

April 12, 2022

We are thrilled to announce our new partnership with Napino Auto & Electronics Ltd. A licensing agreement to produce electric motors based on our innovation for the Indian two-wheeler market

Read more

February 17, 2022

We are proud to have teamed with Omega Seiki Mobility, an innovative electric vehicle manufacturer, embracing our patented motor topology

Read more

January 25, 2022

Chosen by ISRAEL21.

Always excited to be listed among the most innovative startups in electrification

Read more

May 5, 2021

New electric motor design revealed that could ‘revolutionize’ EV performance and manufacturing

Read more

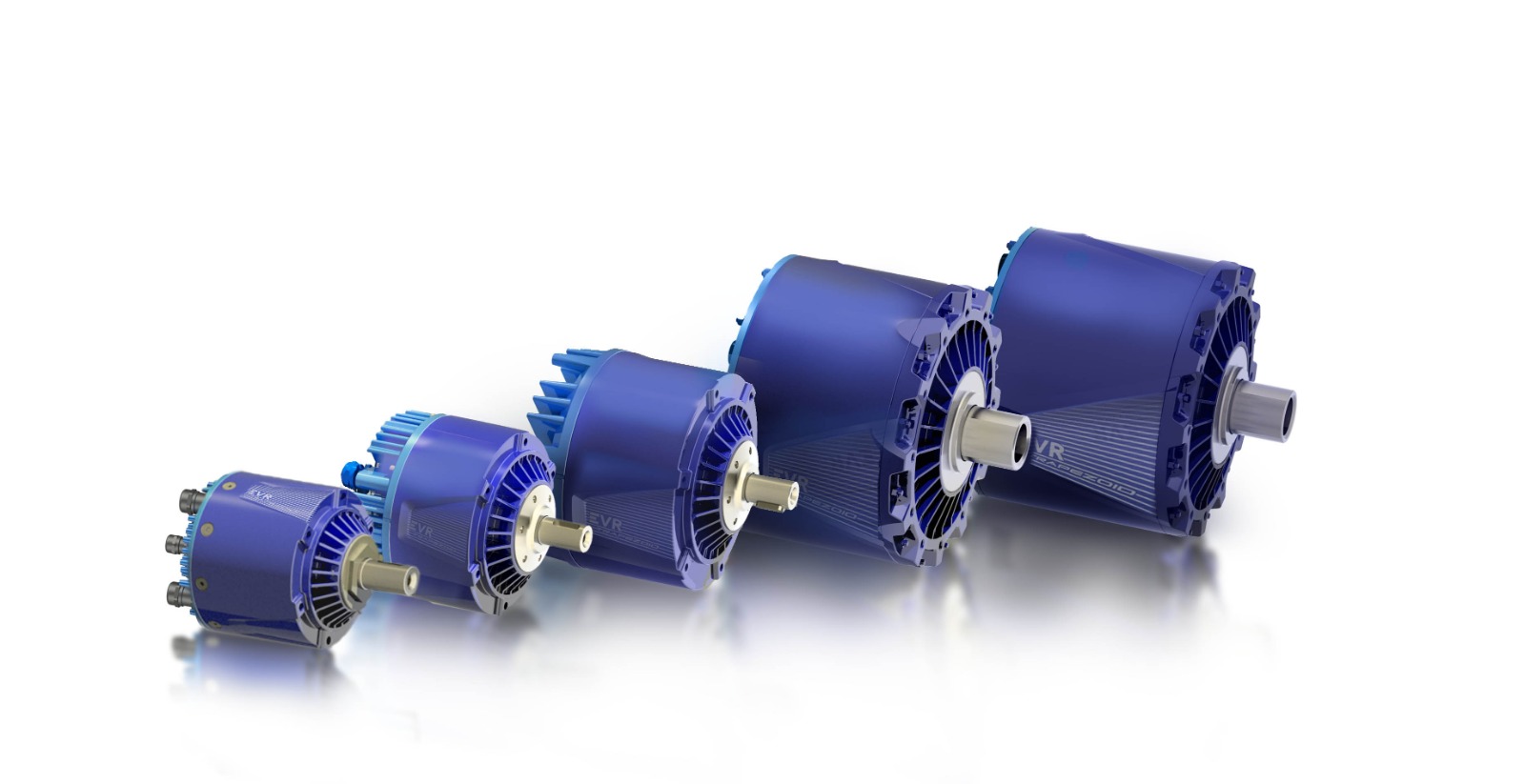

Our Solutions

Our motors can vary in size, power, rotor structure, voltage, cooling method and more – in accordance with specific requirements. Variations are based on unified design and tooling, thereby maintaining low assembly and logistics costs.